|

|

|||||||||

By Val Kraev

Editor's note: Kraev's Korner was first published in the newsletter of the Altshuller Institute, www.aitriz.org, in 2005. Our thanks to the Altshuller Institute and the Technical Innovation Center for letting us reprint this educational series. Previous lessons can be found by searching the TRIZ Journal's archives.

Once we formulate a physical contradiction we can use it for deriving the formula for an ideal final result. The formula of the ideal solution represents a physical model for the development of future solutions. To satisfy opposing physical requirements contained in the model, we need to use separation principles and knowledge from database of scientific effects and phenomenon.

According to TRIZ, the scientific effect is one of the principles for resolving physical contradiction and can be considered a transducer for transformation of one action or field to another with application of physical, chemical, biological and geometrical phenomena. At present time, about 5,000 different effects and phenomena are known; 400-500 effects are the most applicable in the practical activity of engineers.

The application of scientific phenomenon leads us to the development of solution concepts of the highest innovation level since the formulated problem contradiction is being resolved on its physical level. Typically, there are several different approaches in using the scientific effects for problem solving in practical activity – this lesson focuses on two basic methods only.

Let's apply the object-directed method to perfect a typical home vacuum cleaner. We will focus on just one object of the vacuum cleaner – the main tool for cleaning different surfaces – airflow. We will consider four different problems related to vacuum airflow – improving the vacuum design by applying different physical contradictions and scientific phenomena to one object in accordance with the object-directed approach.

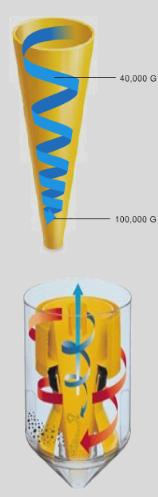

| Problem: When the conventional vacuum cleaner is empty, clean air flows in and out of the machine through the pores of the bag. As you use the machine, the bag fills with dust and debris. The bag acts as a filter and the machine starts to lose suction, because the pores of the bag begin to clog with dust. This restricts the airflow that causes the loss of suction power. Physical Contradiction: The airflow should easily seize particles of dust and contamination to clean surfaces and should easily release these particles for cleaning the output airflow. Ideal Solution: Airflow should itself ensure execution of these mutually exclusive requirements without a bag filter. Scientific Phenomenon: Use the physical phenomenon of centrifugal separation of particles with different masses. The traditional bag vacuum was replaced in Dyson's vacuum cleaner with two cyclone chambers that cannot be clogged with dust. How does a cyclone work? Spinning air creates centrifugal force. A cone shape speeds up the spinning air to create even greater centrifugal forces. Higher speed leads to higher centrifugal force. By making the air stream spin, dirt and debris are subjected to the centrifugal force and are thrown out of the air. Because the airflow is unobstructed there is nothing to clog, so suction power remains constantly high. After the Dyson's outer cyclone has spun out the larger dust and dirt particles, the inner cyclone accelerates the air still further to remove the minute health-threatening particles. (For more information, click here.) |

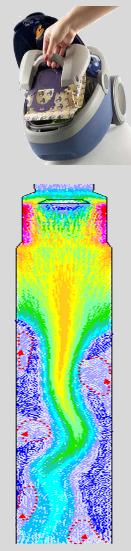

| Problem: Vacuum cleaners are noisy domestic devices. The considerable noise is one of the most serious deficiencies of a vacuum cleaner during its operation. The noise is generated for aerodynamic reasons. To be more precise, noise is generated by the interaction and friction between the high-speed airflow and the fixed structural elements in the input and output of vacuum cleaner. Physical Contradiction: The airflow should have a low friction with fixed design elements to minimize noise and airflow should have a high friction with contaminants to provide high quality cleaning. Ideal Solution: The airflow itself should provide low friction with fixed design elements for lower noise and high friction for capturing contaminants. Scientific Phenomenon: Apply the physical phenomenon of decreasing turbulence in airflow. One of the main causes of aerodynamic friction with noise is the formation of vortexes in high-speed airflow. This physical phenomenon is called turbulence. The Electrolux vacuum cleaner Ultra Silencer reduces noise levels from an average level of 78 to 72 decibels. This means it is four times less noisy than most vacuums. The Ultra Silencer halves the sound twice – creating a quieter, more pleasant way to clean. Electrolux optimizes the airflow system with a system of large, aerodynamically designed air ducts. The machine is also equipped with efficient seals to minimize air leakage and low-noise floor nozzle. |

| Problem: Some vacuum cleaners use rolling brushes to improve cleaning quality. These brushes are inside the nozzle and are gyrated with help of an additional electric motor. This solution makes the nozzle heavy, complicated and expensive. Physical Contradiction: Suction airflow should have a large velocity head for rotation of a rolling brush and should not have a large velocity head that requires more power from the suction motor. Ideal Solution: Airflow itself (without electric motor) ensures gyration of a rolling brush without the powerful suction motor. Scientific Phenomenon: Use physical phenomenon of magnification of a force F by increasing a surface area A on which the airflow pressure P operates: F = PA, without increasing pressure. Inside the nozzle, use a turbine with increased surface area. This surface has a special developed profile (i.e., geometrical effect is also applied) for the best interaction with suction airflow. Airflow rotates a turbine and then the turbine effectively rotates the brush. Having the rolling brush inside the nozzle driven by the vacuum airflow requires no need for extra connector or electrical power. A high-speed rolling brush can agitate the dust deep inside of any carpet for easy cleaning. A transparent cover enables the user to see dirt – or a problem in the nozzle – clearly and completely. In this example the new geometrical and physical phenomena of aerodynamic head pressure are being used jointly with the turbine wheel serving as mediator. |

| Problem: Conventional robot vacuum cleaners do not remove contaminants completely, especially fine contaminants embedded in a carpet or stuck to the cleaning surface. This is because the force at the suction port is generally not strong enough to completely remove all contaminants embedded on the surface. The customer tried to increase the suction force by using a more powerful driving motor, but this increased the noise and the overall dimensions of the vacuum. Physical Contradiction: The force from the airflow at the suction port should be strong for removing the fine contaminants and should be weak for decreasing the electrical power consumption and noise. Ideal Solution: Airflow at the suction port should itself provide force on the fine contaminants at the suction port and preserve low-powered suction. Scientific Phenomenon: Use the physical phenomena of agitating the dust under vacuum by injecting exhausted airflow of vacuum into the suction port. |

The object-directed method allowed us to develop a system with new functions: bagless airflow self-cleaning, reduction of the turbulence noise, better cleaning with a rolling brush and increasing the cleaning of fine dust.

Now, we will consider the other method, function-directed, and will focus on providing different scientific effects for just one function.

| Object: The top-loading washing machine with a vertical rotating drum. The main function of this machine is cleaning different linen. Problem: The function of cleaning in a washing machine is accomplished by the penetration of washing liquid through the linen, thus removing contaminates. For increasing cleaning quality in such a machine, it is necessary to increase the speed difference between the linen and washing liquid at the rotating drum. Formulating the physical contradiction in this problem is related to the parameter of speed difference: this speed difference should be large for better cleaning and should be small because linen is rotated together with washing liquid in one drum. The washing liquid itself will provide the requisite speed difference during rotation in the drum – this is an ideal solution. Scientific Phenomenon: Use a geometrical effect. In the center of the drum, an agitator with special geometrical form is installed. The inner drum has been removed from the outer drum. It is resting on the gearbox, and the plastic agitator is visible in the center of the tub. Due to the agitator's complicated geometrical shape, the washing liquid is rotated faster than the linen. |

| Can we clean using just some interaction between the washing liquid and the linen without a typical washing machine? How? Formulate a new physical contradiction: the washing liquid should move with some pressure and friction relative to the linen for cleaning and removing contaminates, and should not move without driving drum. Scientific Phenomenon: Use the physical phenomena of ultrasonic cavitation. The ultrasonic washing machine has no movable parts and can wash the linen with tiny cavitation bubbles from acoustic and ultrasonic waves in the washing liquid.

|

| Can we achieve the ideal solution that the clothes clean themselves? Scientific Phenomenon: Apply chemical effect of photocatalytic reaction. Scientists have built a thin layer, or "nanostructure," using minute particles of titanium dioxide that reacts with sunlight to break down dirt and other organic material and can be coated on cotton to keep the fabric clean. The clothes simply need to be exposed to natural or UV light for the cleaning process to begin. Once triggered by sunlight, clothing made out of the new fabric will be able to rid itself of dirt, pollutants and micro-organisms. Even though the idea sounds futuristic, developers believe the technology could be in everyday use in the near future. Several companies interested in making the concept a commercial reality have already approached the scientists. (For more information, click here.) |

| Scientific Phenomenon: Use biological effects. One idea is based on the lotus plant, whose leaves are well known for their ability to 'self-clean' by repelling water and dirt. One reason the lotus leaves are so water-repellent (and self-cleaning) is that their surfaces contain countless miniature protrusions coated with a water-repellent substance. Water cannot spread out and attach to the leaves. Instead, water rolls around as droplets, removing grime and soil as it moves. To mimic this effect, the developers use silver nanoparticles – 1/1000th the thickness of a human hair – in its new coating. The particles create miniature protrusions on the fabric while a polymer coating binds them permanently to the fabric. Unlike today's water-repellent coatings, which wear off over time, the new coating permanently bonds to the fibers. It is a polymer film called polyglycidyl methacrylate. Since it only alters the surface of the fibers, it can be applied to any commercial textile, including polyester, cotton and silk. (For more information, click here.) |

| Another option is using a biological agent, bacteria, which can clean. The garments in our wardrobes may be able to support a variety of safe bacteria engineered to eat odor-causing chemicals and human sweat. Other bacteria might secrete waterproof and protective coatings to extend the life of clothing or produce antiseptic for bandages.

|

The object-directed method is preferable for the customer from an economic point of view. It allows for maintaining the basic technical system, importing into it only the additional changes. The physical properties of the selected component are transformed to the new functions or new consumer's characteristics of the improved system. New ideas from this method do not require expensive changes and proposals can be introduced quickly into manufacturing. Thus, the innovation level of these developments is "good enough," but not of the highest order.

The function-directed method of investigation of scientific phenomena application is more efficient and moves the system closer to the ideal system because it is interlinked with the desire to achieve the demanded function without a technical system.

The function-directed method leads to big changes in the technology or system and simultaneously leads to deriving the best results at the highest innovation level. The practical activity shows that the customer treats the new function-directed proposals guardedly because their introduction into manufacturing requires substantial process changes, time and expenses. This approach can be used with excellent results for forecasting projects, implementation related to next generation and evolution of the systems and technologies.

Now there are special tables of application and descriptions of scientific phenomena. Usage of these tables provides an opportunity to define the required effect of an output action or function that should be performed in accordance with the problem.

Also, there are special software with databases of scientific and engineering effects, and phenomena. These programs allow you to select effects based on the desired function. Some software provides you with access to more than 4,500 engineering, scientific effects and examples with descriptions of theorems, laws and phenomena.

Utilization of scientific phenomena and effects helps approach the ideal solution because these effects resolve intensified physical contradiction. Scientific effects are used together with other TRIZ tools including inventive principles and standard solutions.

In conclusion of this lesson, using scientific effects and phenomena help an inventor to develop solutions at the highest innovation level as the formulated problem contradiction is being resolved at its physical level. The object-directed method defines application of new scientific phenomena for one element or one object of the system. The function-directed method is devoted to development of one function of the system with improvements coming from the different scientific phenomena and effects. Application of each these methods depends on specific customer and inventive situation needs.

What kinds of phenomenon are used in the problem-solving processes described below?

| Problem: Sometimes attempts to twist off a tight bottle cap do not work due to a poor grip. Answer: Use a simple flat elastic band. When the rubber band is wrapped around the bottle cap, it increases gripping friction with a larger diameter to hold. |

| Problem: In a bathroom after taking a shower, the wall mirror becomes misted and is difficult to use. Answer: The mirror in a bathroom will not become misted if you rub the mirror surface with a solution of 1 teaspoon of gelatin in 50 ml. of water. |

| Refrigerator Noise Vibration and noise from an old fridge can be annoying, particularly at night. Replacing the refrigerator with a new one is expensive. Moving this noisy appliance to the basement is not convenient for cooking. How can we solve this problem by applying scientific effects? |

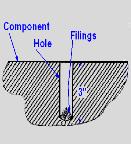

| Filings How can we remove filings from a deep hole with a small diameter after drilling or threading into a steel component? You could use a vacuum cleaner or magnet but the hole is too deep and small. Nor can we turn the component upside-down to remove the filings. |

| Fluid Management Sometimes we need to decant some perfume from a large bottle with very narrow neck to a smaller bottle with a very narrow neck – quickly, without losses. Can a physical effect help? |

Val Kraev is the chief TRIZ officer of the Technical Innovation Center in Worcester, MA, USA, and has contributed several very valuable case studies to The TRIZ Journal. Contact Val Kraev at kraev (at) triz.org or visit http://www.triz.org.