Ñ å ê ö è ÿ 1 ÐÀÑÏÐÎÑÒÐÀÍÅÍÈÅ ÒÐÈÇ Â ÌÈÐÅ

FUTURE OF CAE AND TRIZ

Seung-Hyun Yoo, Department of Mechanical Engineering, Ajou University, Suwon

Vice President of Korea TRIZ Association, Korea

Abstract

In this paper current CAE systems are studied and future CAE systems are projected following evolution patterns in TRIZ. The fast developing hardwares and softwares will fundamentally change our CAE systems providing tremendous computing power. The shape of CAE systems in near future is predictable from the ideality of TRIZ. Also the current education systems of mechanics and CAE should be changed fundamentally. New version of research and educational CAE systems according to new paradigm is proposed and the relation between CAI (Computer Aided Innovation) is discussed

Introduction

Modern enterprises need new innovation tools to adapt to rapidly changing environments. In addition to these methodologies, modern companies confront radical innovation. [1,2,3] Radical innovations require 3 elements, namely new to market, 5~10 times performances, and 30~50% cost reduction. It is our confession that current curriculum and engineering practices can not meet these requirements. The author has been teaching mechanical engineering concentrating on engineering design. He has been desperately trying to find a systematic tool for innovation, creativity, inventions and designs. Current curriculum of mechanical engineering consists of some basic sciences like mathematics, physics, chemistry and mechanics such as statics, dynamics, solid and fluid mechanics, thermodynamics and design practices from element design to system design. Those are core disciplines called engineering sciences and their primary goals are to understand the materials and systems and predict or simulate the behaviors. Considerable achievements have been made not to allow dramatic failures except some historical cases (for example Hyatt regency hotel in Kansas city accident 1981) and to make robust estimation of durabilities. But these mechanical improvements do not guarantee commercial successes. Some technological breakthroughs are required in addition to fancy designs. So a new paradigm for the product development is sought and CAI (Computer Aided Innovation) can be an answer for that question. The Korean economy achieved 10,000$ per capita income and now in a stalemate. So all of the Korean country are trying to make innovations in every field from industries to education systems. Naturally CAI including TRIZ softwares are rapidly gaining momentum for practical applications. In this paper, the author tries to find the relations between current CAE (Computer Aided Engineering) systems and TRIZ principles. The understanding will lead us to figure out the future of current engineering practices.

CAI and TRIZ

In this paper CAI means mainly TRIZ. So the most popular softwares such as Goldfire Innovator, Innovation Work Bench, and CREAX are the items relevant to the topic covered in this paper. [4,5,6] One important theme of the development principles of technological systems is MATChEM (M : Mechanical A : Acoustical, T : Thermal, Ch: Chemical, EM : Electromagnetic). This paper uses this MATChEM concept and Ideality to relate CAE and TRIZ.

Current status of CAE

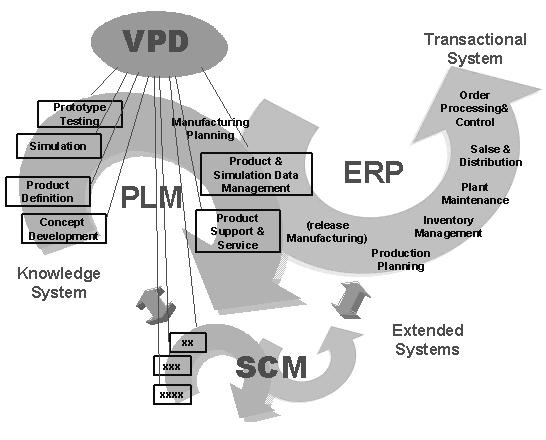

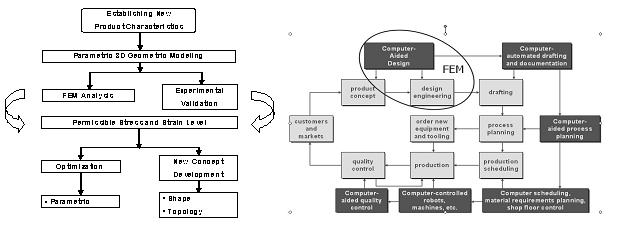

CAE plays critical roles in product development and realization processes. In a broad sense all engineering disciplines belong to CAE as nowadays no engineering disciplines work without computational help. But CAE consists of following items when we narrow the definition. Fig.1 shows their roles of VPD(Virtual Product Development) in digital enterprise including ERP(Enterprise Resource Planning), PLM(Product Lifecycle Management) and SCM(Supply Chain Management). [7] Also the positioning of the FEM (Finite element method) can be expressed as in Fig. 2.

Creative efforts are needed to achieve innovations but there were no systematic method except so called serendipity until TRIZ is introduced. The cover page article in PRISM, which is the official magazine of ASEE (American Society of Engineering Education), on summer issue, 2004 exemplifies the same situation in the Unites States. In this article, they confessed that there was no specific method to improve creativity even though the creativity is such a critical element in engineering education. Also they pointed out TRIZ as a potential solution for this deplorable situation. [8]

Figure 1. Virtual product development processes

Figure 2. Finite element method in CAE processes

Also Prof. Flowers of MIT pointed out that creativity is so important that 'informed creative thinking' must be taught at the annual ASEE conference at June of 2004. The reason is that smart students can be obtained by outsourcing but the leadership can not be outsourced. In addition to that point he declared engineering science is dead and real engineering is needed in engineering education. It sounded to me that TRIZ must be explored more even though CAE is still important. [9]

Evolution of FEM

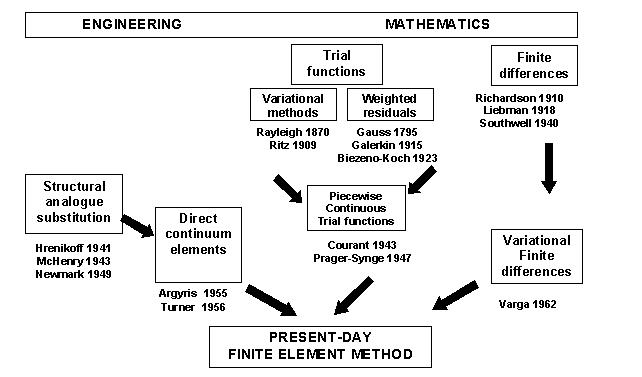

Simulations of the behaviors of product are necessary for good designs. Mostly the governing equations are given as differential equations and the final problems become BVP (Boundary Value Problems) or IVP(Initial Value Problems). Analytical solutions can be obtained for simple geometries with simple conditions and exhaustive solutions are documented for many cases. Many eminent applied mathematicians and engineers contributed on those exact solutions, but most real problems do not allow analytical solutions. Then we should resort to numerical methods such as FDM (Finite Difference Method) and FEM. The discretization methods are developed for this purpose and FDM has longer history than FEM in this sense. But FEM plays more important role as the de facto standard method. FEM uses 'Divide and Conquer' concept and discretizing techniques. As shown in Fig. 3, FEM has developed into current form by combining variational method and weighted residual method. [10] The continuous trial functions are applied to discrete structures such as trusses at first and extended to continuum objects. The modern concept of the FEM was initiated in 1950's while the implementation was done in 1960's. Core concepts were ripe during 1970's and extended to every possible problem after computers were introduced and increased their capacitances. Naturally FEM was applied to structural analysis first and the 3 dimensional formulation was established. Ironically the solution process is easier for 3D problem than 2D problems such as plates and shells. Next the FEM solved more PDE (partial differential equations) which govern stress and thermal problem. They are the first phase of MATChEM and the very mechanical problems. Usually PDE's are categorized into elliptic, parabolic, and hyperbolic types. The stress analysis problems are elliptic and the thermal problems are parabolic. The third is hyperbolic problems and the representative problem is wave propagation problems.

Figure 3. Development of the modern finite element method

Mathematical solutions had long histories for this type of problem, but practical application of FEM to this kind appeared around 1970's much later than former two types. [11] The solutions of wave phenomena are A (Acoustical) in MATChEM. Next applications are on chemical problems where the mass transfer is the most important distinction between mechanical and chemical analysis. The practical finite element solutions appeared on mid 1980's long after the mechanical solutions. Recently electro magnetic problems are analyzed by finite element method. It is wondrous for the author that the development of finite element and application procedures followed the basic concepts of TRIZ even though it has been developed independently for long time. Recent report on the research direction in computational mechanics, where the main tool is finite element, selected following items as the main themes to dig into in future. Virtual design, multi-scale modeling, adaptivity, very large-scale parallel computing, biomedical engineering and controlling uncertainty. [12]

Engineering Design

Engineering design can be divided into formative design and creative design. The formative design is incremental design, routine design, improvement, optimization, and compromise. Creative design is innovative design and aim at implementing original concept beyond current paradigm. Even though the importance of creative design is recognized, there are no other methods than TRIZ to enhance systematic creativity in real world problems.

Future of CAE

The relationship between TRIZ and CAE or FEM is investigated from the history of FEM. The first applications of primitive form of FEM were on discrete structures and extended to continuum problems. This process can be considered as an example of 6th rule in patterns of evolution, increasing complexity, and 4th rule, increasing dynamism. And the development of modern FEM follows exactly same patterns of MATChEM from the emergence of the first paper on those topics. Although the origin and main concepts are mathematical and computational, the patterns of evolution of the FEM are amazingly same as those by TRIZ. The future of CAE or FEM is predicted forming the extension of the line of evolution pattern. Certainly CAE will advance in the direction of increasing ideality. From the research items in the report [12], the patterns of TRIZ can be matched as follows.

Virtual design: As the system evolves increasing ideality, everything will be designed using field concept instead of substances. So the CAE systems will be virtual.

Multi-scale modeling: So far FEM is used for continuum level simulation. But the capability of FEM will be on meso and quantum level. Naturally multi-scale modeling will be essential feature of future FEM. This is exactly same as 7th rule of the TRIZ pattern, transition from macro to micro.

Adaptivity: This can be matched with 2nd rule, increasing ideality, 4th rule, increasing controllability and 8th rule, increasing automation.

Very large-scale parallel computing : There are two ways to handle big computational tasks. One is to develop faster chip and build so-called supercomputers. But this trend has inherent limitation and increase the expenditure very much. The other approach is to use parallel systems. This method is good to make super computing power using normal pc's. Also it is well known that new projects are developed to use idle computers to solve big problems which can not be solved by one super computer. World Community Grid is one example of that kind of efforts. [13] This matches well with main concept of TRIZ, which stresses 'use of every possible resources'.

Biomedical engineering: The other big area for future engineering application is BME(Biomedical engineering). Recently biomimetics and TRIZ are combined together for creative design methodology. One of the future challenges of FEM is also for exploration of living systems.

Controlling uncertainty: This can be matched with 8th rule, decreasing human involvement or increasing automation.

When we apply IFR to the computer systems, the final computing will be done without expensive hardwares or system softwares. Every engineer can do realistic simulations without profound knowledge on finite element theory or computing systems and languages. My graduate students are working at CAE teams of big companies showing their expertise on FEM. But soon they should demonstrate another capability of creativity when FEM become a routine engineering task. So far there is a specialty called 'numerical analyst', but the name will be disappeared soon. That is also the reason that students of engineering science should learn TRIZ more seriously. The ideal final CAE systems will free the engineers from solutions of difficult differential equations and long hours to use FEM proficiently. By then the engineers can concentrate only on creative and innovative idea generation. [14]

Future of engineering design education

Current engineering discipline spare much credits on mechanics and engineering sciences for future application on CAE. They are essential courses to make good engineers. But this composition should be reconsidered as the total credits for graduation is decreasing. As an alternative curriculum, need based curriculum is proposed instead of discipline based curriculum which is now prevalent over the world. [15] The effects module of Goldfire Innovator is a good example of this kind of approach.

Conclusion

In this paper the main concepts of TRIZ are related with current practices of CAE and FEM. The close matching of patterns of evolution of TRIZ with development of FEM is verified. The future of CAE systems is predicted from extending the line of evolution pattern and IFR concept. So the reason why engineering students should learn TRIZ more seriously and engineers should prepare for next paradigm of engineering design is shown. Simulation will be done automatically and creative output will be the last measure of engineers. Naturally, engineering curriculum must be changed to lead the paradigm change and this will be the tasks for current engineering professors.

References

1. Leifer, R., et. al, "Radical Innovation: How Mature Companies Can Outsmart Upstarts", Harvard Business School Press, 2000

2. Stefik, M. and Stefik, B. "Breakthrough : Stories and Strategies of Radical Innovation" , The MIT Press, 2004

3. Sun, W., "Strategy to connect manpower of industries and universities", Mechanical Engineer's Day Conference, 2004

4. Goldfire Innovator software manual, www.invention-machine.com

5. IWB software manual, www.ideationtriz.com

6. CREAX software manual, www.creax.com

7. MSC.Software Professional Services Overview, MSC.Software Corporation, 2003

8. McGraw, D., "Expanding the mind", PRISM, Vol.13, No. 9, pp. 30-36, ASEE, 2004

9. Flowers. W., Plenary Talk, ASEE Annual Conference, June 27, 2004

10. Zienckiwicz, O.C., Taylor, R. L. and Zhu, J. Z, "The finite element method", Butterworth-Heinemann, 6th ed., 2005

11. Bettess, P., and Zienckiwicz, O.C., "Diffraction and refraction of surface waves using finite and infinite elements", Int. J. Numer. Methods Eng., Vol. 11, pp. 1271-1296, 1977

12. Oden, J. T., et. al., "Research directions in computational mechanics", Comp. Meth. in Applied Mech. and Eng., Vol. 192, pp. 913-922, 2003

13. World Community Grid Hompage : http://www.worldcommunitygrid.org/

14. Leon, N. and Martinez, O. "Product Optimization vs. Innovation, Steps toward a Computer Aided Inventing Environment", Proc. TRIZCON 2003, Philadelphia, PA, pp. 2-1 ~ 2-12, March 16-18, 2003

15. Yoo, S.-H., "Designer's Creativity", Ajou University Press, 2004 (in Korean).

Âîçâðàò ê Äîêëàäû íà êîíôåðåíöèè "MATRIZ Fest 2005"

|