|

"ÒÐÈÇ-Êîíôåðåíöèÿ - 2007" Ñïèñîê ó÷àñòíèêîâ è òåìàòèêà âûñòóïëåíèé

The TRIZ Give Way to the Wind, and Give the Wind Away

A Repeatable Process for Improving Sustainable Wind Energy Generation

Author

Isak Bukhman, TRIZ Master

Abstract

Given the fast growing population and the ever increasing consumption of resources it is imperative that breakthrough innovations make alternative energy sources more commercially viable. Wind turbines represent an attractive source of sustainable and environmentally friendly energy. World wind energy capacity has been doubling every three years during the last decade and growth rates in the last two years have been even faster. Yet the technology still needs a higher profile and greater efficiency.

Using the improvement of Wind Turbine Development as a case study, this presentation focuses on a proven and repeatable process that overcomes common TRIZ deployment challenges by showing a workflow and methodology for how to get started working on a problem with TRIZ, how to compliment TRIZ with Value Methodologies for problem identification, and how to leverage internal and external knowledge sources to accelerate concept identification.

Introduction - Wind Turbine Development

The potential for wind energy production is yet to be realized, but holds great promise for as a renewable and environmentally friendly source of energy.

- Wind power is expected to grow at an annual rate of 20 % resulting in a total of about 40 000 MW of installed capacity around the world by 2004.

- According to recent study “Wind Force 10” wind power could generate 10 % of global electricity by 2020, and create 1,7 million jobs at the same time.

- International installation of 1,2 million MW of wind capacity by 2020 would generate more electricity than the entire continent of Europe consumes today.

- Total wind energy potential in the world is 53 trillion kWh, 17 times higher than the Wind Force 10 goal.

- According to the study the cost of generating electricity with wind turbines is expected to drop to 2.5 US cents/kWh by 2020, compared to the current 4.7 US cents/kWh.

- Environmental benefits of the 10 % target would be enormous – savings of 69 million tones of CO2 in 2005, 267 millions tons in 2010 and 1780 million tones in 2020.

The potential for TRIZ as a high-value problem solving methodology has also yet to be fully realized, especially in combination with Value Engineering and a fund of targeted informational resources. But with an effective roadmap to guide the practitioner, the benefits of combining and deploying these discrete resources and methodologies are readily attainable. This paper describes such a roadmap and thereby provides a repeatable process for improving not only sustainable wind energy generation, but a method for improving virtually any technical system.

Project Description & Initial Situation

We have selected Three-Blades Turbine as a base Turbine design for our research project. The Three-Blade Turbine is most common, sometimes known as a Danish Concept. These three-bladed wind turbines are operated "upwind," with the blades facing into the wind. Wind turbine works the opposite of a fan. Instead of using electricity to make wind, a turbine uses wind to make electricity. The wind turns the blades, which spin a shaft, which connects to a generator and makes electricity. The electricity is sent through transmission and distribution lines to a substation, then on to homes, business and schools.

We have selected Three-Blades Turbine as a base Turbine design for our research project. The Three-Blade Turbine is most common, sometimes known as a Danish Concept. These three-bladed wind turbines are operated "upwind," with the blades facing into the wind. Wind turbine works the opposite of a fan. Instead of using electricity to make wind, a turbine uses wind to make electricity. The wind turns the blades, which spin a shaft, which connects to a generator and makes electricity. The electricity is sent through transmission and distribution lines to a substation, then on to homes, business and schools.

Information Gathering

Identify and define the component structure of the wind turbine

Identify trends of past and present R&D efforts that have contributed to current utility-scale turbine technology

• Improvements in the aerodynamics of wind turbine blades, resulting in higher capacity factors and an increase in the watts per square meter of swept area performance factor.

• Development of variable speed generators to improve conversion of wind power to electricity over a range of wind speeds.

• Development of gearless turbines that reduce the on going operating cost of the turbine.

• The general trend is toward wind turbines with maximum power output of 1 MW or more. European firms -- such as Danish companies Vestas and NEG Micon -- currently have more than 10 turbine designs in the megawatt range with commercial sales.

• Wind turbine manufacturers optimize machines to deliver electricity at the lowest possible cost per kilowatt-hour (kWh) of energy.

• Development of lighter tower structures. A by-product of advances in aerodynamics and in generator design is reduction or better distribution of the stresses and strains in the wind turbine. Lighter tower structures, which are also less expensive because of material cost savings, may be used because of such advances.

• Smart controls and power electronics have enabled remote operation and monitoring of wind turbines. Some systems enable remote corrective action in response to system operational problems. The cost of such components has decreased. Turbine designs where power electronics are needed to maintain power quality also have benefited from a reduction in component costs.

System Functional Analysis

A functional model of the system is nessesary to obtain a proper understanding of system behavior. Each component and function must be defined.

Advanced function analysis allows us to define parameters of functions, their actual and required values, and their dependencies.

The completed full function model will document the system sufficiently to enable the recognition of problematic areas in the system. Additionally, the documented model permits an in depth automated evaluation from a Value Engineering perspective.

Model Data Device Diagnostic: Component Parameters and rating help define strategies for subsequent changes or simplifications of the system configuration. A variety of criteria can be evaluated in order to select strategies that best align with the project goals.

Design Simplification Strategy - Trimming Method

- Improves product/process by eliminating low value (problematic) components and redistribution their useful functions between other components.

- Simplifies and reduces the cost of user product/process, while preserving the essential functionality.

- The design variants that results from Trimming will generate different problem statements, if solved, can lead to highly innovative solutions.

Wind Turbine -> trimming scenario results

1. Low-speed shaft, Gear box, High speed shaft, Wind wane, Wind direction data, Pitch (mechanism) were trimmed.

2. Stator of AC Generator connects Hub.

3. Hub rotates Stator of AC Generator

Pre-Problem Selection

We have selected one problem (pre-problem) for the next stage of the project: The value of the torque parameter, which describes the effect of the action push (rotate) by the wind (wind energy) on the Blades (three), is 2000 Nm. The required value of this parameter is 4000 Nm to provide to increase efficiency of blades. The problem is: How to increase the torque of the Blade?

Algorithm for Inventive Problem Solving – Part 1

INITIAL SITUATION ANALYSIS – Selection of Mini-Problem

Algorithm for Inventive Problem Solving – Part 2

PROBLEM MODEL ANALYSIS - List of resources of space, time, substances, (parameters), and fields

Algorithm for Inventive Problem Solving – Part 3

DETERMINATION of IFR (Ideal Final Result) and PC (Physical Contradiction)

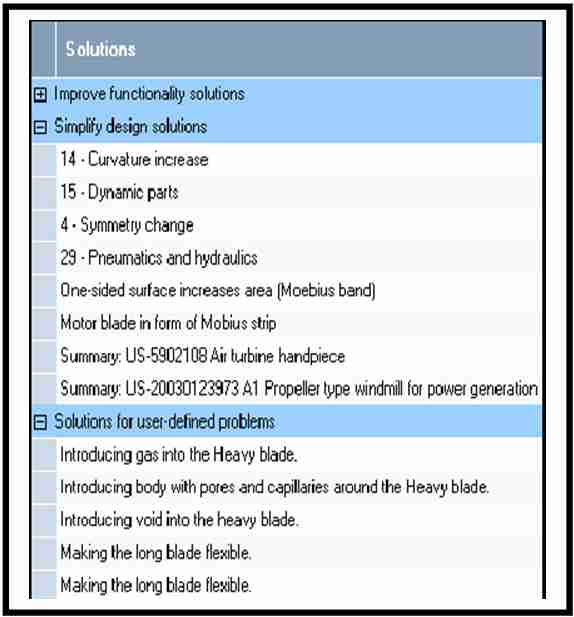

Concepts Evaluation & Selection

We created 32 available solutions for farther development by using TRIZ, Value Engineering, and Informational Fund (Scientific Effects Library, Patent Collections, WEB based information), including:

- 9 - From the Inventive Principles

- 2 - From the Effects Library

- 12 - From the System of Standards

- 9 - From Patent Collections and Web based information

Solutions must be ranked to help decide which ones to research further and implement.

Conclusion - Best Solutions

In total, 6 concepts were ranked as high level available solutions, having the ranking equal or higher than 10, including:

1. Stator of Permanent Magnet Synchronous Generator directly connects Blades.

Blades rotate directly Stator of Permanent Magnet Synchronous Generator.

Permanent Magnet Synchronous Generator works good for variable blades

|

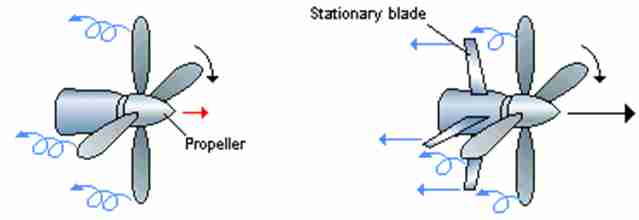

2. Doubled Propeller - Doubled Blades.

The propeller is the contra rotating with a diameter of 4.5 m (14 ft 9 in).

It has blades made of advanced composites and pronounced scimitar-like curvature on the leading-edge. It offers increased efficiency under high-speed cruise, and improved acoustics.

|

3. Efficient propeller - Efficient blades.

A propeller produces a propulsion that drives an airborne vehicle.

Disadvantage: This causes an air stream to be driven back, causing high turbulence. This decreases the propulsion.

|

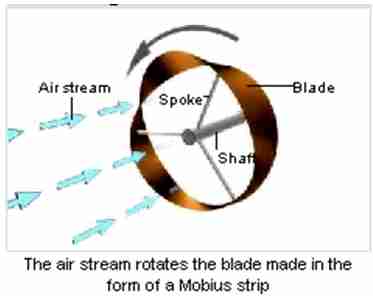

4. Blade in form of Mobius strip.

A blade is fixed on a shaft by means of spokes. The blade is made of elastic material and has the Mobius strip form.

Advantages:

1. The propeller blade in the Mobius strip form is simple in design.

2. The blade in the Mobius strip form is easy to manufacture.

|

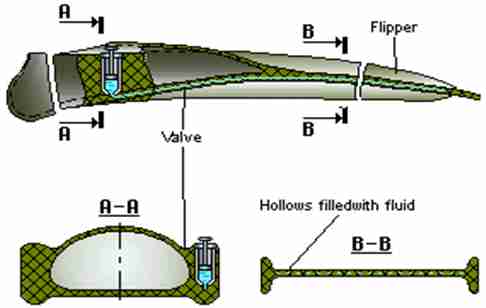

5. Variable-rigidity flipper - blade.

Different rigidity is required in swimming flippers under different water conditions (governed by speed and length of stay).

It is proposed:

to use hydraulic constructions and variability (dynamism) to improve the flipper design. One can form an enclosed longitudinal hollow in the elastic flipper material. This is filled with an fluid whose pressure can be adjusted using a piston valve. High pressure makes the flipper blade rigid. This can be adjusted to optimize for current swimming (wind) conditions

|

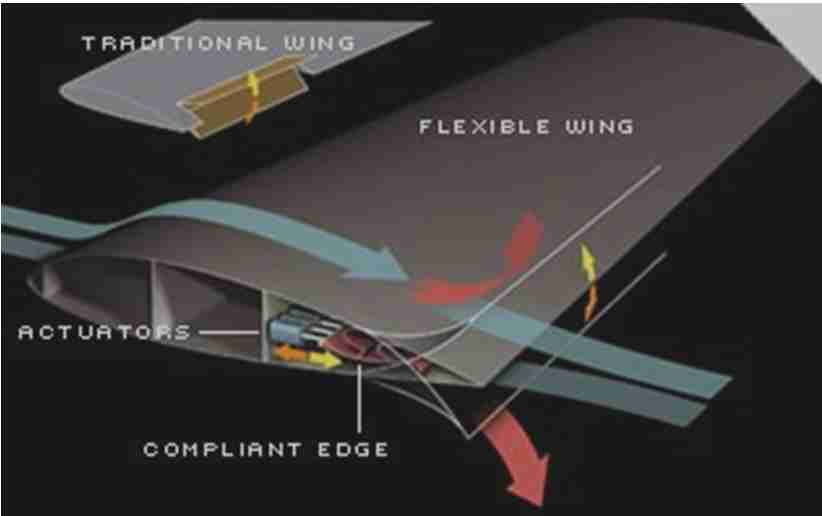

6. Flexible wing - blade.

|

This repeatable process overcomes common TRIZ deployment challenges by showing a workflow and methodology for how to get started working on a problem with TRIZ, how to compliment TRIZ with Value Methodologies for problem identification, and how to leverage internal and external knowledge sources to accelerate concept identification.

About the Author:

Isak Bukhman is a TRIZ Master, Value Methodology (VM), and 6Sigma certified specialist with more then 30-year practice in the product/process development and manufacturing areas.

Isak has spent 7 years at IMC (Invention Machine Corporation) as their Chief Methodology Specialist and now works as independent consultant.

He guided development of innovation projects for several world leading companies such as Philips, Mattel/Fisher-Price, Microsoft, Shell, Samsung, POSCO, Masco-Behr, Medtronic, Xinetics, Henkel, Delphi, Baker Hughes, Baosteel, etc.

He has delivered numerous basic and advanced training seminars (some of them together with Genrich Altshuller), and educated and trained more than 1000 Managers, Engineers, and Researchers in TRIZ/Value Methodology, and in Product/Process Evolution and Development.

In 80's Isak dedicated about 7 years for children/juniors education of creativity.

tel: (617) 926-7145 cell: (617) 218-7415 Skype id: bukhman

Isak-Bukhman@comcast.net

|