|

|

|||||||||

By Val Kraev

Editor's note: Kraev's Korner was first published in the newsletter of the Altshuller Institute in 2005. Our thanks to the Altshuller Institute and the Technical Innovation Center for letting us reprint this educational series. Previous lessons can be found by searching the TRIZ Journal's archives.

TRIZ standards are a set of generalized rules and formulas for solving common problems that are found in the work environment. Standards are employed in finding inventive solutions to typical (or standard) inventive problems. The standards contain clear instructions for how an initial technical system should be transformed in order to solve the problem. These rules are recommendations based on the analysis of past inventions that solved similar problems. Consequently, these rules are sometimes termed as "standard solutions."

Historically, the standards have been developed over time as the strongest combinations of several principles and physical effects. The first group of standards was developed in 1979 using Genrich Altshuller's method of s-field analysis. An s-field is a simple graphical model for describing an inventive problem and a useful, visual method of expressing both the initial situation and the solving process. The standards essentially have grown out of the process of perfecting the inventive principles, s-field analysis and modeling.

Each s-field consists of at least two substances (S1 and S2) and a field (F). Analysis of the s-field helps determine the changes necessary to improve the technical system. This analysis is usually carried out in the operating zone (OZ) where the problem occurs. The most important feature of s-field modeling and standards application is the formal process of transforming the initial problem model to the recommended solution s-field model. This process is implemented without directly formulating a technical or physical contradiction, because that concept is already accounted for in the s-field model.

| This picture is the most basic example of an s-field model. It shows the format used to represent the interactions between the substances and field. To provide a function, the s-field must have a minimum of three basic elements:

Lines between elements show interaction between elements. Interactions can be useful, harmful, unregulated, poor or absent. |

In s-field analysis the word "field" is used conditionally. It does not mean only physical fields such as gravitational, electromagnetic, thermal and so on. It can also mean different kinds of technical and non-technical "fields" like mechanical, inertial, light, olfactory, biological, etc. These fields include any interactions between substances that produce the required result.

In s-field analysis the word "field" is used conditionally. It does not mean only physical fields such as gravitational, electromagnetic, thermal and so on. It can also mean different kinds of technical and non-technical "fields" like mechanical, inertial, light, olfactory, biological, etc. These fields include any interactions between substances that produce the required result.

Some fields that can be considered during s-field analysis and modeling include:

Today's standards form a system that includes 76 standards in five classes. The order of the classes corresponds to the trend toward increased ideality.

(The standards of the second and third classes are founded on the use of patterns of system evolution, including deployment-convolution, improvement of dynamicity and controllability, transition to a microlevel and coordination-mismatch.)

We will explore, by using concrete examples, the application of some standards from each of the five classes for solving simple problems. During the solving process, the initial problem situation is matched up with one or more standards, which suggest the generic formula of the solution for the inventive problem. The generic solution recommends implementing some function (for example, putting in a new substance or field, using a physical or other effect, synchronizing a rhythm or frequency, or using a hollow or empty space). There are some simple steps for using standards for problem solving:

|

Class 1. The Building and Destruction of S-fields First, we can determine that the problem is related to changing the initial model (i.e., it is not a measuring problem). Then, we develop an initial s-field model for our situation: assign S1 to the screw (it is a product and we will not modify it) and assign S2 to the screwdriver (a tool that needs to be improved). Assign F – do we have a force to hold the screw to the screwdriver? The problem is that our screwdriver cannot hold the screw. This is a typical problem with an incomplete s-field model. It contains only two substances without any interactions between them. (See Figure B.) In this case, the standards suggest completing the s-field with the application of rule 1.1.1: Standard 1.1.1. Construction of a complete s-field: If there is an incomplete S-field that is difficult to control (and by the conditions of the task, there are also no limitations to introducing other substances and fields) the problem may be solved by making a transition into a complete s-field. In order to realize this recommendation, we have to apply a field F as a third obligatory element to complete the initial s-field model. What kind of field can we use in this situation? Since we are dealing with a metal screw and screwdriver, we may use their strong magnetic properties as shown in Figure C. The magnetic field of the screwdriver would hold a screw. What is the simplest way to give a magnetic field to the screwdriver? Rub the metal end of the screwdriver on the surface of a permanent magnet for about fifteen seconds. After that procedure, the screwdriver's metal end will generate a magnetic field and will keep the screw in place easily as shown in Figure D. Problem. While painting, we have to pour out some paint from the can, but the only readily available container is a saucepan. (See Figure E.) How can we avoid dirtying or spoiling the pan with the paint or other chemical substances so we can still use it for cooking? Standard 1.2.1. Introduction of a third new substance. If there are useful and harmful interactions between substances in an existing s-field (while it is not necessary to preserve immediate contact between them) the problem may be solved by the introduction of a foreign substance between them that is free or relatively inexpensive. According to this standard, we have to introduce a foreign substance S3. (See Figure G.) between the saucepan, S2, and the paint, S1. The new substance must be free or relatively inexpensive. In order to protect the saucepan from paint or other chemical substances staining it, place a plastic bag in the pan as shown in Figure H. This bag will protect the saucepan from direct contact with the paint, while the main function of the pan, holding the paint, will remain. A bag would be easily available at home, cheap and can be fixed with an elastic band or string around the edge of the pan. After completing the paint job we can remove the plastic bag from the pan. As a result, the surface of the pan is protected from the harmful chemicals in the paint so it can be safely used for cooking again. |

|

Problem. While painting, we have to pour out some paint from the can, but the only readily available container is a saucepan. (See Figure E.) How can we avoid dirtying or spoiling the pan with the paint or other chemical substances so we can still use it for cooking? Standard 1.2.1. Introduction of a third new substance. If there are useful and harmful interactions between substances in an existing s-field (while it is not necessary to preserve immediate contact between them) the problem may be solved by the introduction of a foreign substance between them that is free or relatively inexpensive. According to this standard, we have to introduce a foreign substance S3. (See Figure G.) between the saucepan, S2, and the paint, S1. The new substance must be free or relatively inexpensive. In order to protect the saucepan from paint or other chemical substances staining it, place a plastic bag in the pan as shown in Figure H. This bag will protect the saucepan from direct contact with the paint, while the main function of the pan, holding the paint, will remain. A bag would be easily available at home, cheap and can be fixed with an elastic band or string around the edge of the pan. After completing the paint job we can remove the plastic bag from the pan. As a result, the surface of the pan is protected from the harmful chemicals in the paint so it can be safely used for cooking again. |

|

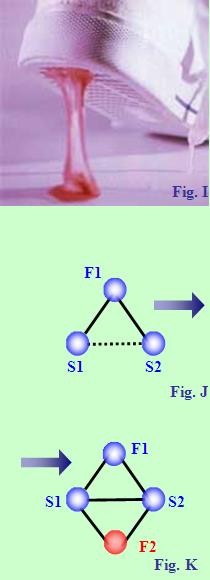

Class 2. The Development of S-fields Problem. Imagine a disagreeable situation in which you wish to remove chewing gum stuck to your footwear or clothes. Simple mechanical removal and washing do not produce acceptable results. (See Figure I.) How can we clean the gum off the clothes simply and promptly? Let's try to solve this unpleasant problem with s-field modeling. Our clothes are shown as a product S1, the chewing gum is a tool S2, and the unregulated adhesion force of the gum is F1, which is what makes this situation difficult. (See Figure J.) The unregulated interaction between S1 and S2 is represented by a dashed line. This is a typical problem that requires further development of an s-field, and we will apply the second class of Standards for its reconstruction: Using this standard, we can develop our initial unregulated s-field model into the new double s-field as shown in Figure K. We have to find a second field, F2, which will help us to control the adhesion force F1 and remove the gum easily. Use a thermal field, specifically freezing. If we apply a piece of ice to the gum, the gum freezes and becomes solid. After that we can remove the gum from our clothes. Alternately, we can use a home freezer to accomplish this unpleasant task. |

|

Class 3. The Transition to Supersystem and to Microlevel Problem. How can you prevent odor and fungus in your socks, even when you are active all day? (See Figure L.) You could change socks more frequently, but this may not be reasonable. What else can be done? The problem is related to the change of an initial s-field model. We can redesign that model for this case and denote the human body, feet, as the product S1, the sock as a tool S2, and the biological field between them as F as shown in Figure M. After a while, an odor and even fungus may appear on the socks and feet. This is a serious problem that can be solved with the application of Standard 3.2.1. Application of this rule leads to a transformed s-field model with a new substance S2*, which was modified on the micro-level and can provide a new action – protection against odor and fungus when it interacts with the biological field as shown in Figure N. Military PX stores sell the ArcticShield polyester "stink-proof" nano socks from ARC Outdoor. They incorporate 19-nm silver particles within their fibers. Well-known for its antimicrobial properties, silver has been used to provide protection against odor and fungus in socks. Outdoor clothing suppliers will begin carrying nano-enhanced jackets, gloves and bibs from ARC as well. These socks are included in the top ten of 2005 nanotechnology products by Forbes. |

|

Class 4. Standards for Detection and Measuring Problem. To be accurate, when you need to drill holes to a required depth you have to interrupt your drilling to take measurements. This is a difficult process that takes a lot of time. How can you simplify this task and do it faster? The problem is related to the fourth class of standards because it requires measuring: We have to change this task in accordance with the above standard. For instance, if we could see the hole that we are drilling, we could wind several layers of tape around the drill bit at the required height. Then we would be able to gauge the depth of the hole during the drilling process without interrupting it. We can easily apply this standard to solving our problem. Apply tape over the length we'd like to measure. Then we can mark or cut the tape, remove it and measure it easily. |

|

Class 5. Standards for Application of Standards |

My own experience of standards application in practical activities confirms that many problems can be solved with this relatively simple and logical tool in a short time. Manufacturing engineers like to work with the standards of the first three classes because these proposals are simple and lead to non-fundamental changes in the initial system with good results and, therefore, can be realized quickly and without big expenses.

Standards are widely employed in forecasting projects. Standards of the fifth class are used when it is necessary to develop or to improve existing design or technology. These proposals use inventive by-pass methods, system resources and scientific phenomena. However, practical implementation of these solutions requires a long time and large expenses.

Note that the development of an initial s-field model is the most important and non-trivial stage of standards application. Sometimes we can develop several different s-field models for one problem situation and find the solution depends completely on initial information about of the problem. Therefore it is important to get a full picture of the problem and the interacting elements that will form the s-field model for the solution. The standards allow us to solve relatively non-complicated or typical problems.

Standards are structured rules for the synthesis and reconstruction of technical systems. Standards provide different functions:

S-field modeling of a technical system is performed in the operating zone, the area where the core of the problem and actual contradiction occurs. In an s-field at least two substances and a field must be represented. Analysis of the s-field model helps to determine the changes necessary within the technical system in order to improve it. Once understood, and with some experience in their implementation, standards can help combat many technical problems.

What classes of TRIZ standards are used in the problem solving process described below?

| Problem. It is convenient to collect leftover metal chips with the use of a magnet. This method is especially effective when metal dust is being gathered. However, a different problem comes up when separating the metal dust from the magnet itself. Tape can be used as a solution but in that case, the metal dust and the tape both have to be thrown away because it would be too difficult to separate them again. Can you propose another method? Answer. In order to conveniently collect the metal dust without dirtying the magnet surface – and without wasting scotch tape and the time needed for separation – we can wrap the magnet in cloth, a plastic bag or paper. Under the magnetic field the metal dust will gather on the surface of the intermediate material. When the magnetic field is removed they can be separated easily. |

| Problem. When we chop onions, they irritate our eyes and sometimes even drive us to tears. How can we preserve our eyes from the irritation caused by chopping onions, garlic or horseradish? We could use swimming goggles, but they are not comfortable or convenient to use during cooking and are not often found at home. Can you propose a simpler solution for solving this unpleasant home problem? Answer. In order to preserve the eyes from the irritation caused by chopping certain foods, apply airflow from a fan. This airflow will remove irritating substances from the cooking area and our eyes. We can solve this problem relatively easily and without looking like a bug-eyed monster while we cook. |

| Screw Problem It is both an old and a new problem. Once again, we need to insert a screw into a deep horizontal hole and the screwdriver cannot hold the screw. Standards tell us that in this case we have an incomplete s-field model (just two substances) and suggest using "something else" between the screwdriver and the screw. Try creating a field between the substances by using a magnetized screwdriver to hold screw. But if you have a non-magnetic screw, what can you do? Can another TRIZ standard help us? |

|

Thermometer Problem |

|

Bulb Problem |

Val Kraev is the chief TRIZ officer of the Technical Innovation Center in Worcester, MA, USA, and has contributed several very valuable case studies to The TRIZ Journal. Contact Val Kraev at kraev (at) triz.org or visit http://www.triz.org.