Manufacturing Lead Time Reduction

When selecting a vendor for a particular component a satisfactory answer to a question – when will you deliver, often outweighs a satisfactory answer to a question – how much will it cost me. However, an answer to a first question may be erroneous as it is, usually, based on the project management concepts and tools that are too linear and deterministic. The systems in which project management occurs are too complex and volatile and contain too much apparent randomness to be managed effectively by the linear, deterministic tools that focus on one portion of the system at a time. A cause-effect chain type analyses are but one example of such a tool – too linear and deterministic.

In my career, I participated in vendor selection process as both – a vendor and a customer. There are numerous reasons for why the delivery may be more important than the price. This paper does not address these reasons; this paper is a compilation of methods, used in the process of a reduction of product lead time from 14 to 8 weeks.

A manufacturing company, XYZ, discussed here, designs and builds certain equipment for power plants. It takes an average 14 weeks to design, manufacture and deliver the equipment after the receipt of the order. The customers considered the lead time very excessive and, as a result, the company was facing a potential of losing many of its customers. The situation was aggravated by the fact that the selection and sizing of this particular equipment took a back seat to most of power plant design activities, in which XYZ has no responsibility. In addition, the equipment, supplied by this company, is installed during power plant construction. Thus, an additional pressure from a general contractor, who is responsible for delivery, based on his own commitment. Presently, many large projects suffer from cost overruns and scheduling delays. Moreover, as projects get more complex, as completion time becomes more critical and as concurrent design and implementation (such as fast-track construction) becomes more prevalent, failure to meet project goals is likely to become increasingly common.

The situation with problem solving is very similar. A cause-effect chain, used in the analytical phase of a problem solving process, is too linear and deterministic. The integration of system dynamics into problem solving process has not yet happened. This is a pronounced deficiency, especially true for analysis of business/management processes/systems.

This short paper does not allow for a detailed description of a project. However, here is one illustration of the importance of the integration of system’s dynamics into a problem solving process.

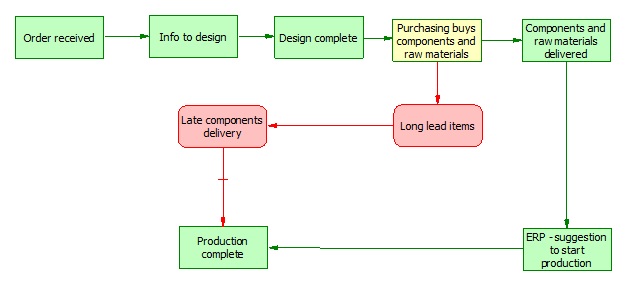

Back to XYZ. One particularly long lead item was determined through the Level 1 and 2 Pareto analyses. The Pareto analyses were supported by cause-effect chain, which looked as follows:

This diagram was constructed with Innovation WorkBench software, IWB, by Ideation International. The Problem Formulator module of IWB is, in my opinion, best suited for construction of such diagram. The notation suggests that the long lead item interferes with the efforts to complete production. Therefore, late shipment and, as a result, unhappy customer.

Upon analyses of the situation, it became apparent that the one particular long lead item should be processed in such a way as to not cause delay in order shipment.

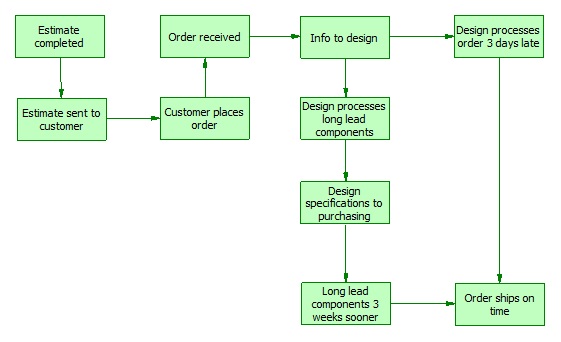

The conventional cause-effect chain did not produce a satisfactory solution. However, upon completion of the causal loop diagram the solution became apparent.

Process long lead items first. The main sticking point was delaying design on the entire order for 3 days. However, by looking at the system as a whole we realized that the overall order lead time was kept to our commitment.

I realize that this paper does not start to describe Causal Loop Diagram and associated analyses process. Therefore, I will publish a more detailed article on the subject of system dynamics and causal loop diagram based analyses.